Process-optimisation systems

Solutions for manufacturing, production logistics and shipping

Create transparency

In addition to classic signal devices, WERMA offers intelligent solutions that make Industry 4.0 tangible, tangible and immediately implementable in practice. Our solutions are ready-made, can be used immediately and function "out-of-the-box". Because WERMA takes signal technology a step further!

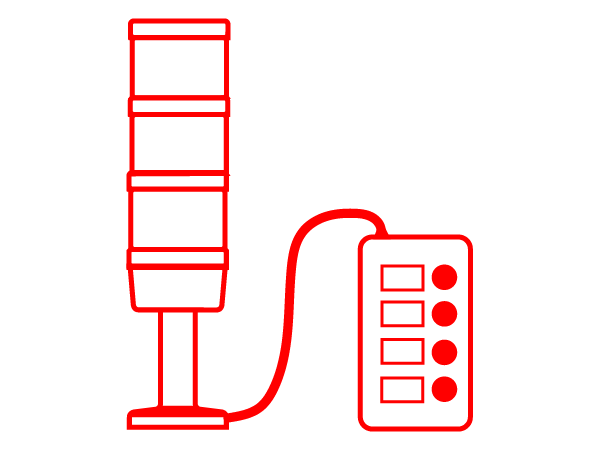

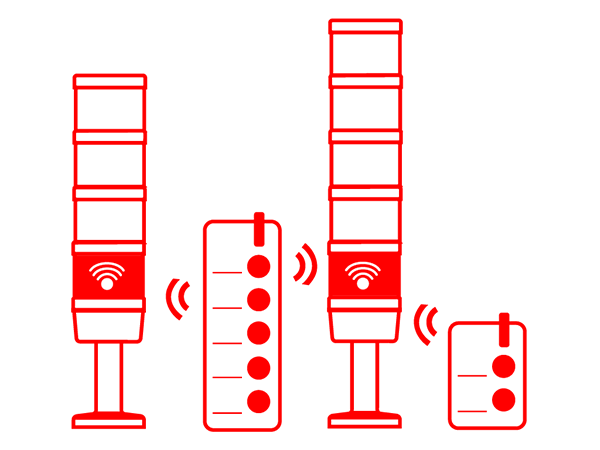

With our call and signal systems (AndonLIGHT, KombiSIGN Reflect and AndonWIRELESS) you can quickly and easily report problems at manual workstations and control access to doors and gates without the need for monitoring software.

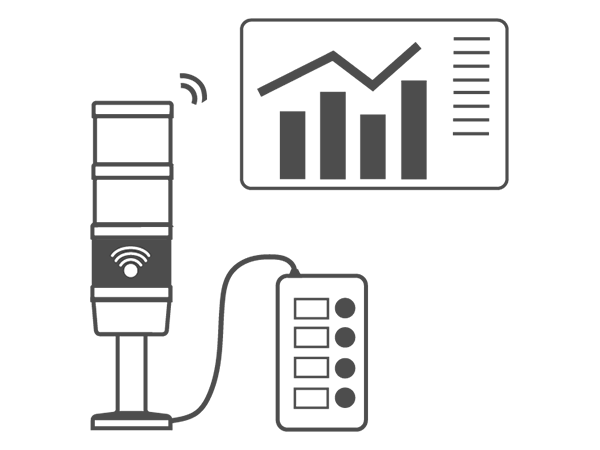

Thanks to our clever solutions (AndonSPEED, SmartMONITOR and WeASSIST) with monitoring software, you can detect weak points immediately. To uncover hidden potential in manufacturing, logistics or mail order, you need a system to measure unproductive times - whether at manual workplaces, dispatch workplaces or in automated manufacturing.

Overview of advantages:

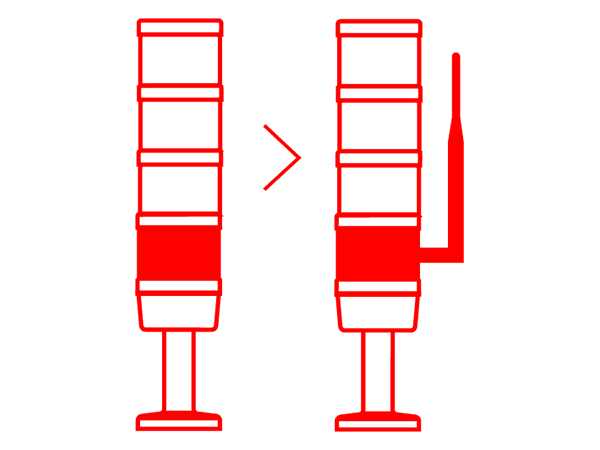

- Independent of other systems and easy to retrofit

- Identify weak points quickly and clearly to increase productivity

- Central control station collects statuses from all workstations and machines

|

Degree of digitization

|

Without monitoring software

|

|

Function / Benefits

|